A Brief Introduction to the gearbox design

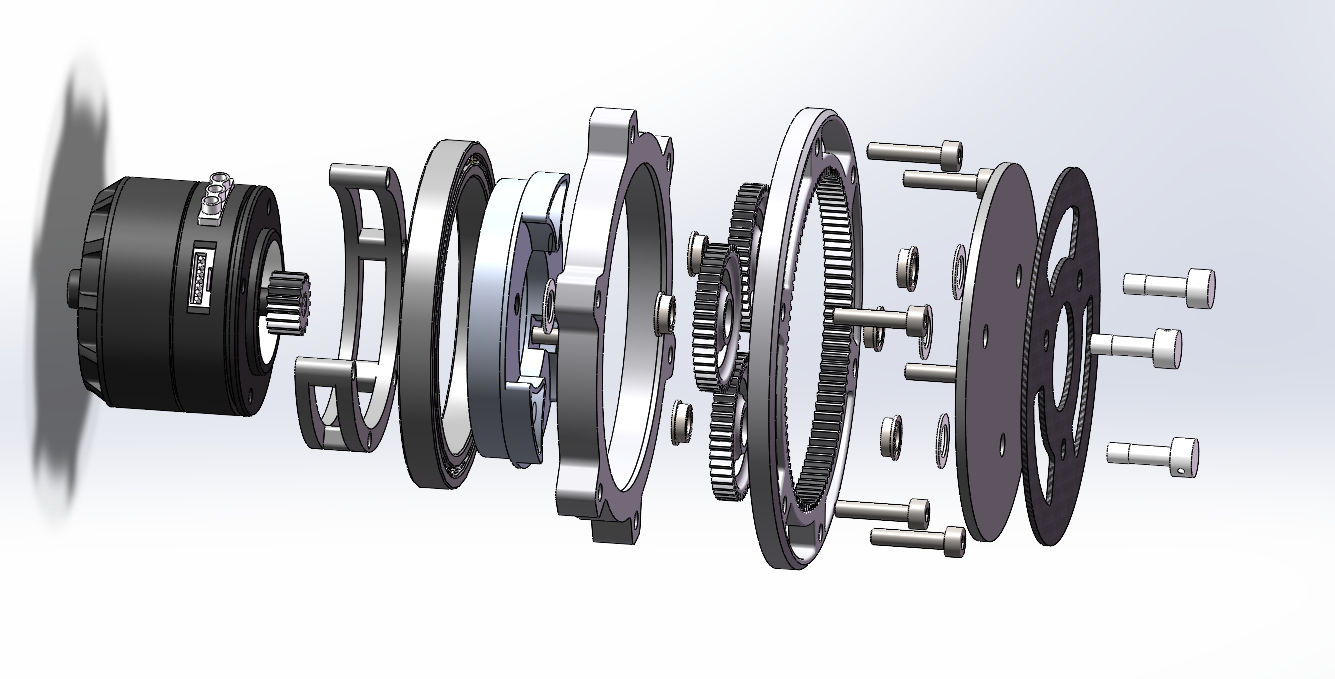

The necessity of designing the gearbox is listed in chapter 3.2.2. Since the original gear ratio is 1:19 and the ratio should be or close to an odd integer, the first ratio was chosen as 9 or 11. Firstly the type of the gearbox was chosen as cycloid reduction gearbox for this type can achieve a big reduction ratio using a little space. But when designing, the standard parts limit the design. Balancing pros and cons, the design was later on changed to planetary gearbox to achieve a simpler structure. Since it is a 2K-H type gearbox, so with m = 0.6 and the number of teeth on the ring of 186, the diameter of the ring will reach about 130mm and disturb the design of the wheel diameter. Due to the ratio function of the second-stage gearbox, so when the teeth of the gear is 53 and 31 respectively, the final ratio is 10.1574.

After the project of “High-dynamic, wheeled-legged bipedal robot system based on an LQR framework for Whole Body Control.”, the actual torque needed for a robot about 20kg in weight can be read directly from the hub motor. Working backwards, the torque should be about 1.5Nm. So in the planetary version, the ring have 119 teeth. In this version, the single-sided hub can also act as an outer retaining edge for the bearings, so it is possible to make the entire reduction gearbox part of the wheel.

All parts of the gearbox is made by 6061-T6, a somehow extreme design because of the limit of budget. Due to the starting torque formula, the starting torque of the M3508 motor’s should be 4.4Nm, thus that of the driving part’s should be 0.232Nm. Furthermore, the gear’s thickness is 4mm. Sufficient redundancy has been considered.

For the outcome of this design, the rotate time reduce from 1s to 0.3s in comparison to the Mecanum Wheel version of the robot under about the same working conditions.

Images of the robot

The nylon proofing and exploded view of gearbox assembly

Related videos

The video of Infantry rotating under 100W power limit of the chassis. The rotating speed of 0.3s per round is taken from this video.